Arrows – TYPES AND CONSTRUCTION

An arrow is a fin-stabilized projectile that is shot with a bow. It consists of a straight shaft with point on one end, and fletching and nock on the other end.

The shaft is the primary structural element of the arrow, to which all the other components are attached. Traditional arrow shafts are made from strong, lightweight wood, bamboo or reeds. Currently the best wood material is cedar. These all are unique and largely inconsistent in their attributes – straightness, strength, gauge. You may have to test many shafts to get a dozen that perform consistently. Manufacturing advances have brought about modern shaft materials where tolerances are virtually the same. Such shafts are typically made from aluminum, carbon, or a combination. These are chosen by most competitive archers.

Arrow shaft measurements:

Spine? The stiffness of the arrow shaft is known as the “spine”. This refers to how little the shaft bends when compressed by the launch from the bow (kinetic energy from the bow pushes the arrow). There are devices that test the strength of a shaft. Higher draw-weight bows will generally require stiffer spined arrows. Do not shoot wood arrows from a compound bow as most can not handle the kinetic energy from the bow design, the result may be that the arrow breaks/splinters upon release!

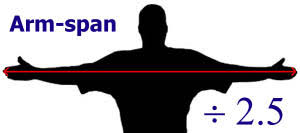

What is your draw length? Make sure your arrow is long enough. Quick check is to hold the arrow in both hands perpendicular to your chest, nock on chest. Point of arrow should be at least an inch beyond your extended fingers.

Grains? This is a unit of weight measurement. The weight of an arrow shaft is measured in grains per inch (GPI). The length of your arrow shafts must be cut exactly the same and individually measured on a grain scale. You will gain performance by having arrows that are exactly the same.

Arrow repairs – at this rank level you will be building a simple arrow. As you progress in the program, more advanced techniques will be addressed.

Fletchings are found a the back of the arrow. They act to stabilize the trajectory of the arrow, correcting for paradox and drift by producing spin. This is similar to how a football, or bullet, flies through the air accurately because of spin, as opposed to tumbling. Arrows without fletchings are called “bare shaft”. These may be used to test consistency of arrow shafts and sometimes the archer’s consistent performance. This will be discussed in later ranks.

Fletchings may be of natural feather or plastic “vanes”.

Feathers are usually made from goose or turkey. Natural feathers are prepared by splitting and sanding the quill before gluing or binding to the shaft. With conventional three-feather design, one feather is called the “cock” or “index” feather. It is always positioned at right angle to the nock. It then faces away from the bow as to not interfere with the release of the arrow. It would glance the bow each time and deflect the trajectory. Four-feather designs are symmetrical and there is no preferred orientation for the nock, this makes nocking slightly easier but reduces the arrows performance and may interfere with the archer’s anchor. Feathers may also be trimmed and customized into a shape by die-cut or burning with a hot electrically-heated wire method (more later).

Vanes are generally plastic or mylar, and come in many colors and shapes. These are glued or have adhesive tape attachment to the shaft. Shaft cleaning is critical in preparation for attaching vanes to secure a lasting bond (more later).

A nock is a notch in the rearmost end of the arrow. This is what attaches the arrow to the bowstring. It helps keep the arrow correctly placed on the bowstring by friction fit. (We show you how to test this “fit” later on.) You have seen pictures of primitive nocks just being a carved “V”. Most modern nocks are plastic. These are glued on the shaft or pushed into an insert. Accuracy is enhanced with a nocking point on the bowstring. This assures the arrow is positioned in the same level spot each time.